Members area

Iscriviti alla nostra area utenti per visualizzare i listini prezzi e le nostre offerte periodiche

Discover the efficiency and precision of laser cutting for metals with Incisman. With state-of-the-art machinery, the company offers solutions for cutting steel, aluminum, copper, brass, and many other materials, ensuring impeccable and customized results. Optimize your industrial projects with a tailor-made service.

Numerous industries require machines suitable for laser cutting metals such as iron, steel, stainless steel, galvanized steel, brass, copper, and aluminum. Is this what you are looking for?

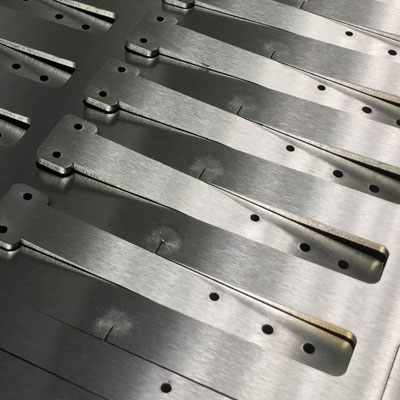

Incisman specializes in laser cutting of all types of metals. The company's state-of-the-art machines are fast and extremely precise, ensuring a clean, burr-free cut.

Application

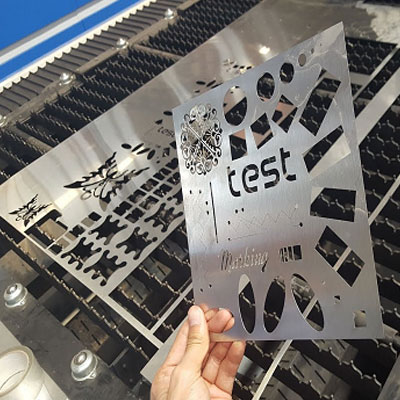

As mentioned, Incisman is capable of cutting various metals, including iron, steel, stainless steel, galvanized steel, brass, copper, and aluminum.

Thanks to their versatility, the machines can also be used for cutting or processing:

items that are difficult to process with other systems;

steel sheets;

components for armored doors;

sheets up to 1 cm thick.

Our customers also contact us for the creation of supports for various applications, such as engine parts or components for the military and aerospace industries.

Given the countless uses of metal and the existing variants, fiber laser machines can also be used for series production of jewelry, eyeglass frames, manufacturing of any sheet metal frame, or steel plates.

Why it makes sense to entrust us with the service

The use of fiber optic laser technology is primarily concentrated in large industries due to the large size of the machines, which require high power consumption. Even smaller versions have high energy requirements. These machines consume a lot of energy.

Our customers, therefore, delegate the metal laser cutting service to us because the costs – between the purchase and maintenance of the suitable machines – are extremely high.

Cutting-Edge Technology

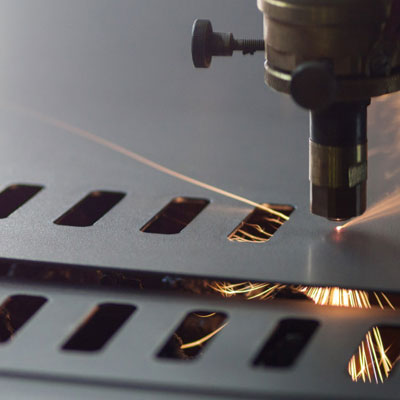

Fiber laser cutting machines are similar to pantographs. However, instead of a rotating spindle, they are equipped with a head featuring a lens system that focuses the laser beam on a single point of centesimal dimensions, facilitating and optimizing the cutting process.

These systems, which operate on three or more axes, allow the cutting of various metals through a laser diode source transmitted via a fiber optic system. The efficiency is about 100 times higher than gas sources.

The technology behind these machines is of European or Japanese design. The laser sources are IPG (American) – the best currently on the market. The structure is treated at 600°C and cooled for 24 hours to ensure a lifespan of 20 years and precision during processing.

Guarantees

Incisman conducts precise tests to ensure the alignment and accuracy of the rails. It uses an autocollimator that provides high-resolution execution accuracy.

To test precision, compensate, and adjust errors, an original interferometer of English design is used.

Internally, the machines are equipped with systems for automatic pressure regulation of the injected gas. The motors used are inertial servomotors from Sanyo or Panasonic, imported from Japan. The transmission system on rails and pinions is from Wittenstein Alpha, the world’s number one German company.

Operation and Advantages of Fiber Laser Cutting

In fiber lasers, the beam is generated using a so-called seed laser and is amplified through specially mounted glass fibers, which are powered by pump diodes. The wavelength of fiber lasers is 1 nm.

The main advantages of fiber laser cutting include higher efficiency compared to CO2 lasers, the ability to cut non-conductive metals such as brass, copper, and aluminum, higher speed, and lower maintenance.

Fiber lasers are characterized by higher precision compared to CO2 lasers; their beam is much finer, and the reduced width allows for greater precision. Combined with the ultra-fast speed of brushless motors, this enables the creation of objects with accurate and precise finishes.

Would you like to know more? Tell us about your needs.

Laser cutting is an extremely versatile technology capable of working with a wide range of metals. You can use it to cut materials such as iron, steel, stainless steel, galvanized steel, brass, copper, and aluminum. The precision of the laser allows for clean, burr-free cuts, even on materials that are difficult to work with using other techniques. It is perfect for producing industrial components, mechanical parts, or design details.

Entrusting laser cutting to a specialized company is advantageous because they have advanced machinery, which requires significant investments for purchase and maintenance. Moreover, professional management ensures high-precision results, optimizing production times and reducing waste. The costs of energy, maintenance, and personnel are borne by the company, allowing clients to obtain high-quality products without having to invest directly.

Fiber laser cutting offers numerous advantages over traditional CO2 laser technology. It is more efficient, with up to 100 times higher performance thanks to diode technology transmitted through optical fibers. It allows for working on non-conductive metals like copper and brass, while providing higher precision due to a finer light beam. Cutting speed is faster, and maintenance is reduced, making it ideal for fast, high-quality productions.